In this article, we will explore the ins and outs of cross-link closed-cell polyethylene foam, commonly known as XLPE foam. As part of a series of articles, this piece will guide you through the essential aspects of this versatile material. Let’s dive in and uncover the secrets of XLPE foam.

Step 1: Understanding Cross-Link Closed Cell Foam

What is Cross-Link Closed Cell Foam?

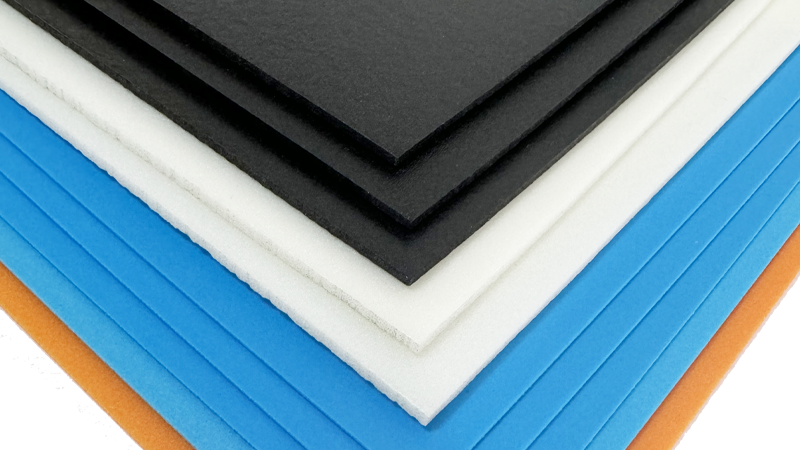

Cross-link closed cell foam, or XLPE foam is a type of foam that is made from low-density polyethylene (LDPE) and other auxiliary materials. It goes through a specialized process of melting, mixing, extrusion, and high-temperature foaming to create a material with a closed-cell structure. This structure gives XLPE foam its unique properties, which we will explore in detail.

Step 2: Raw Materials Used in XLPE Foam

To understand XLPE foam better, it’s crucial to know about the raw materials that go into making it. Here’s a closer look at the four key components:

2.1 Low-Density Polyethylene (LDPE)

LDPE is the main ingredient in XLPE foam, accounting for over 50% of the total raw materials. This material is derived from oil and usually appears in a granular form. LDPE provides the foam with its basic structure and durability.

2.2 Foaming Agent

The foaming agent is typically a powder that plays a vital role in creating the foam’s structure. It has high surface activity, which reduces the surface tension of the liquid mixture, allowing it to surround air and form bubbles. This process results in the foam’s cellular structure, which gives XLPE its lightweight and buoyant qualities.

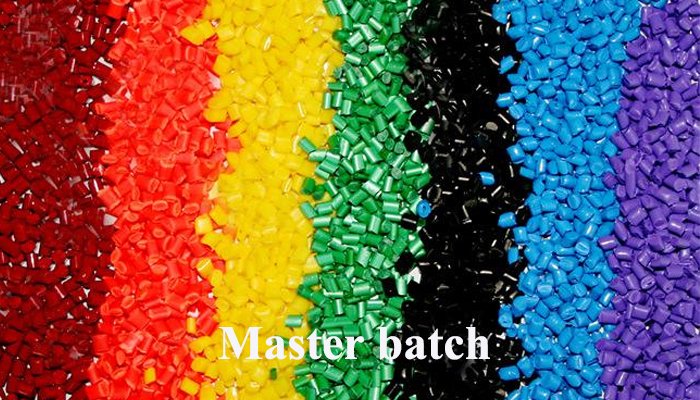

2.3 Masterbatch

Masterbatch is used to control the color of the foam. Different colors require different masterbatch formulations. Standard colors like black, grey, and white are easier to achieve, but producing more complex or vibrant colors can be a challenge. This is why colorful foams often cost more than their monochrome counterparts.

2.4 Other Auxiliary Materials

Apart from the primary components, other auxiliary materials can be added to the mix to enhance certain characteristics of the foam. For example, if a softer or more flexible foam is needed, elastomers may be included in the formula. These additives allow for customization, giving manufacturers the flexibility to create foam with specific features.

Step 3: Unique Features of XLPE Foam

What makes cross-link closed-cell polyethylene foam so special? The secret lies in its closed cell structure, which gives the material several advantageous properties over other types of foam. Let’s break down the key features:

3.1 Thermal Insulation

XLPE foam has excellent thermal insulation properties, making it an ideal material for use in temperature control applications. It helps maintain a consistent temperature by minimizing heat transfer, which is crucial for building insulation, air conditioning, and HVAC systems.

3.2 Waterproof

Thanks to its closed cell structure, XLPE foam is highly resistant to water absorption. This makes it suitable for use in applications where moisture resistance is essential, such as in the construction and automotive industries.

3.3 Soundproof

XLPE foam is also known for its soundproofing qualities. It can effectively absorb and reduce noise, which is why it’s often used in flooring, automotive interiors, and HVAC duct systems to dampen sound.

3.4 Shock Absorption

The foam’s ability to absorb impact makes it an excellent material for packaging and protective applications. It cushions delicate items, protecting them from shocks and vibrations during transport.

3.5 Thermal Forming

One of the unique properties of XLPE foam is its ability to be thermoformed. This means it can be shaped into various forms and contours using heat, which makes it versatile for different industrial applications.

3.6 Conductive / Anti-Static

XLPE foam can be manufactured with conductive or anti-static properties. This feature is particularly useful in the electronics industry, where it helps prevent static electricity from damaging sensitive components.

3.7 Non-Toxic

Another important feature of XLPE foam is that it is non-toxic, making it safe for use in a variety of consumer products, including toys, sports equipment, and packaging for food and beverages.

Step 4: Applications of Cross-Link Closed Cell Polyethylene Foam

Because of its outstanding properties, XLPE foam is used across a wide range of industries. Here are some of the most common applications:

4.1 Construction Industry

In construction, XLPE foam is used as insulation material for walls, roofs, and floors. It helps keep buildings cool in the summer and warm in the winter, making them more energy-efficient.

4.2 Automotive Industry

XLPE foam is widely used in the automotive sector for its thermal insulation, waterproof, and soundproof properties. It can be found in car interiors, under-the-hood components, and even in trunk liners to reduce road noise.

4.3 Flooring and Carpeting

Due to its soundproofing and shock-absorbing qualities, XLPE foam is often used as an underlay for floors and carpets. It provides a soft cushion, reduces noise, and prolongs the life of the flooring materials.

4.4 Air Conditioning and HVAC Systems

XLPE foam is an excellent insulator, which makes it a go-to material for use in air conditioning and HVAC systems. It helps maintain the efficiency of these systems by reducing heat loss and condensation.

4.5 Sports & Leisure Equipment

From yoga mats to protective padding, XLPE foam is a popular material in the sports and leisure industry. Its shock-absorbing properties make it ideal for protective gear, while its flexibility and comfort make it suitable for mats and other exercise equipment.

4.6 Packaging

XLPE foam’s shock absorption and lightweight nature make it perfect for packaging applications. It’s often used to protect delicate electronics, glassware, and other breakable items during shipping.

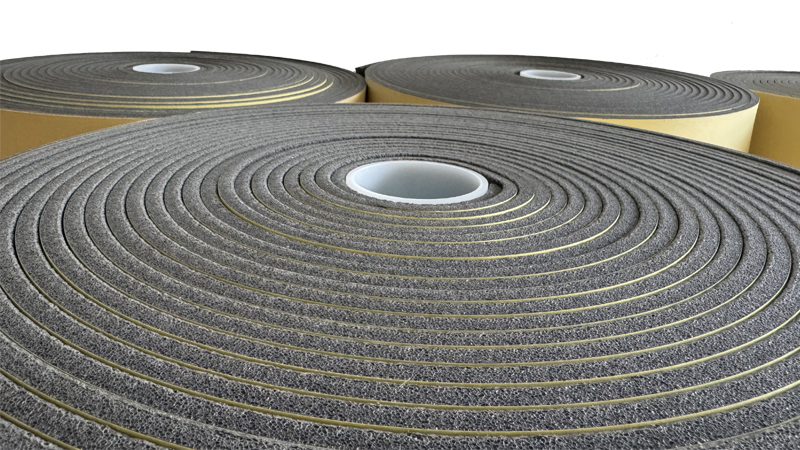

4.7 Foam Tapes

XLPE foam is also used to make foam tapes. These tapes are employed in various industries for applications that require adhesive properties, cushioning, and insulation.

Step 5: The Benefits of Using XLPE Foam

To summarize, here are the key benefits that make XLPE foam a preferred material for so many industries:

- Lightweight – Easy to handle and transport.

- Durable – Resistant to wear and tear, making it long-lasting.

- Versatile – Can be used in a wide range of applications.

- Customizable – Can be tailored to specific needs through additives and masterbatch.

- Safe – Non-toxic and safe for various consumer products.

Conclusion

Cross-link closed-cell polyethylene foam, is a versatile, durable, and safe material with a wide range of applications. From construction to automotive and packaging to sports equipment, its unique properties make it an invaluable asset in multiple industries. Understanding the raw materials, features, and benefits of XLPE foam is essential for anyone looking to use this material effectively. This is just the beginning of a series of articles where we’ll dive deeper into each aspect of XLPE foam, so stay tuned for more insights!